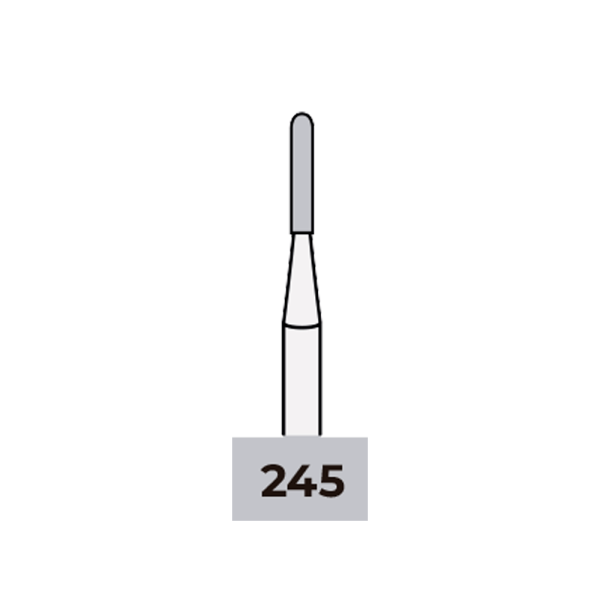

Brocas > Broca Carbide >

Broca Carbide 256 Fg - Kavo

Histórico de preços

Ficha Técnica e Modo de uso:

Broca Carbide 256 Fg - Kavo

Como quem comprou avalia este produto

April 22 2025

Enjoyed the insert overview. I am adding a bit of modern tooling to a 60+ year old hobbyist change gear lathe and like to see what inserts are working well for other folks.

April 22 2025

Thanks for the insight into your bits and such was very helpful for me

Cheers from up North

April 22 2025

For us non-machinists, i consider this to be. "Inserts 101"!

April 22 2025

A beard trim…Happy HD Friday!! I love the intricacies of the machining trades. I am not a machinist, why i watch machining channels. You Ozzies are the best. ✌️from Michigan, U.S.

April 22 2025

Thank you for the video! I have been watching Kurtis over on his channel for the past 3-4 years now and discovered your channel from his. I have no background in machining apart from some CNC back in high school and 3D printing (gcode at least...), but that you for explaining those different inserts! Upstate NY here, btw! Thank you for the videos!

April 22 2025

I am from Poland. Threading - Vargus or Carmex. These are the top 2 among our customers. Drilling - Tungaloy (especially TID / TDX - TID exchangeable heads can be regenrated if you drill a lot), HSS drills - Guhring.

April 22 2025

Matt, for the last month I have been starting my Fridays with you and CEE. That double dose of Aussie helps me get through the crap here in the US, and love the dogs!

April 22 2025

It would be great if you did a video on the composition of insert, ceramic cermet, grades of carbide etc. Thank you for this.

April 22 2025

I wish you would cover the use of trepanning for cutting large diameter holes.

April 22 2025

Thanks Matt.

As a retired mechanic who "plays" with machine shop tool, no one has ever taken the time to explain this and honestly, I never really took the time to look. I just always made what I had work (and that can be interpreted very loosely as to what work means). I just dabble in the dark art of metal removal and still use lots of HSS or cheap Chinese carbide. The lathe I can use has an infinite amount of backlash so I just blame the lathe for all my mistakes.

The shop that has the lathe I can use does not have anyone who knows how to use it, it is a legacy machine left over from an old guy who retired years ago, so anytime I can chuck something up and tune it up a bit or clean it up, they think I am a god. Boy are they mistaken.

I might have to go out and buy a couple of real cutters and see what I can do with it.

April 22 2025

The last time I used a metal lathe was in 1957, when I was in the 9th grade. At that time the tool holder held a hardened, sharpened piece of steel, no idea of what an insert would be. I have thoroughly enjoyed your educational pieces of what a real, modern machine shop actually does. Thanks for giving a view into what goes on both large and small in your world.

April 22 2025

Do you use API qualified full profile threading inserts? Kennametal KC850 tmng 432 or 433 work good.

April 22 2025

Thanks for the review on incerts very informative. I am from the bad old days Pre insert tooling on manual lathe and mill. Spent a lot of time at the grinder and diamond files of CBN to shape the carbide just right. Your drilling review is very informative..Thanks Matt

April 22 2025

As a 70 year old electrical engineer, love learning new stuff every day. Love the video, all the best from Leeds England.

April 22 2025

When are we going to see the drilling machine working.

You promised this ages ago, and nothing since!.

April 22 2025

Matt deine Erklärungen, einfach Spitze. Du kannst jederzeit in Deutschland als Lehrer im Berufsschullehramt Metalltechnik einsteigen. Ich hatte in meiner aktiven Arbeitszeit in unserer Werkstatt Wendeschneidplatten beim Drehen und Fräsen von Kennametal und Iscar im Einsatz . Dieser Kanal ist einfach Super!

April 22 2025

A friend of mine works with airplane engines parts manufacturing. His cutting tools lasts only 3 (three) minutes, cutting exotic alloys, then they are sent to sharpenning and hardening and returns one week later for more 3 minutes of work.

April 22 2025

For Threading I suggest talking to Kurtis at CEE...I believe he uses Palbit Full-Form Threading Inserts for all his Threading needs, though his threads are conventional bolt and nut sizes, not the Insane Monsters you tend to make so I have no clue if Palbit has an Insert that would come close to what you need...

April 22 2025

Excellent video, Matt. I’m not a machinist, in fact I’m barely human. I learned a lot as inserts, and the associated nomenclature were always a mystery - until now. Thank you very much, kind sir. Give your hounds a good hug from me. My best wishes from the other side of our planet.

April 22 2025

Just the video i needed, just purchased used lathe and milling machine and was not sure what carbide inserts to get or what was best for different things. Thank you for explaining difference between each one and what they can and are used for.

April 22 2025

Thx for going into the inserts. It’s always interesting and most guys skip over them. Plus you guys have a good range of uses. Thx buddy

April 22 2025

Hey Matt, one of the other reasons you get less chatter with a smaller nose rad is because the cutting tool is in contact with less material. I chuckled at your tight tolerance of .1 When i was working in tool and die .012 was a very normal tolerance to see. The parts were also 60HRC. You being able to cut those monster threads with such a nice finish is magic to me though. Thanks for the video.

April 22 2025

Great video...wish I had that info 15yrs ago, using inserts at home and was just a lot of suck and see.

April 22 2025

The only thing I have to really correct is that you can absolutely use less than the nose radius, it just has to be a fairly rigid setup. Generally the minimum cut is 1/3rd the radius, where like 2/3rds is the maximum higher feed setup. When you do this you increase the feed to make up for the reduced depth rather than taking a deeper cut, this can often lead to faster paths, or for example in “adaptive” turning it can use a round insert for roughing and take that high feed which optimizes to keep the machine moving smoothly.

April 22 2025

what G codes do you normally use for threading on the cnc lathes? G32 or G92?

April 22 2025

Hi Matt. I live in British Columbia Canada. I stumbled upon your channel several months ago. I am not a machinist but love all things mechanical. I enjoy your videos very much and always learn something new. The machining of some of the massive pieces for the huge drill rig fascinates me. Thank you

April 22 2025

Why all the Machine Tool and Machining talk? I came here to see Murray & Co. stuff.... Thanks for the video

April 22 2025

No Idea what he is saying, I love it. still love this channel with no knowledge whatsoever In machining

April 22 2025

Thank you, for telling me about all of the different inserts for my cutting tools I always was helping somebody would do this video.

April 22 2025

For my home shop and small lathe (12 x 36) and limited budget doing a large variety of projects and fabrications I have been using the chinese inserts. Living on an island in southern Alaska with no machinist tool shops and an order time or three weeks or more they seem to give a good selection and some are better quality than others. Their search engines for tools leave tons to be desired. Very frustrating to say the least. With them I can keep a good stock on hand without having a fortune tied up. Always interested in what a pro thinks of them so an overview would be very interesting. Obviously a pro shop is not going to be interested for himself but he would have a basis of comparison with how big of a gap there is between price and quality. I have never used inserts that are forty or fifty dollars and up so I am short the ability to judge. I also am always on the lookout for inserts with a positive rake for my smaller lathe and for those who can handle harder steels like monel, stainless, etc. Perhaps you can review a few of what is available for those of us whose budgets are tight? Started doing lathe and mill work in my shop twenty five years ago (age fifty) and enjoy most aspects of the manual machines. Very interesting video today. Thanks.

April 22 2025

Hello Matt. Thanks for a great video. I must admit that I had to watch it a few times being a non-machinist. I did learn a great deal. Thanks for taking the time to make the video. It would be interesting to be in your shop for a day. I would probably get kicked out for asking to many questions.

April 22 2025

Love your channel. You present as such a humble down to earth person. Retired from non mechanical career but own a much modified Chinese mini lathe and fascinated by precision engineering. I am always in awe of what you guys do and expect to see your channel grow rapidly.

April 22 2025

Great video but... the crane attached to your head is really off-putting.

Sorry, that sounded more negative than intended. Really great video!

April 22 2025

Great Video EXCEPT….. that crane dead center on the top of your head … was driving me nuts

April 22 2025

What was the book you mentioned in the video? Sounded like would be useful even for blacksmiths?

April 22 2025

Matt, I enjoyed the discussion as I am a home hobbyist, you didn’t include in your review “positive” and “negative” inserts and their holders….when/why to use??? For both rough/finish and materials….still a mystery to me as I make my random choice when manual machining to achieve finishing along with speed/DOC?????

April 22 2025

I am not getting notifications of your videos though I have subscribed to the channel.

Wondering what has gone wrong

April 22 2025

Thanks for the detailed explanation of the tooling you use. We do a small amount of machining here on the farm and are set up with Kennametal tooling. I have learned a great deal by watching your videos. Happy Easter Greetings from Prince Edward Island Canada

April 22 2025

Il video mi è piaciuto molto, grazie. Tuttavia non ho capito che una piccola parte. Sono un principiante. Avrei gradito che tu parlassi di poche punte ma più a fondo, magari con esempi e video dimostrativi. Mi piace la tua onestà intellettuale. Massimo da Roma, Italy

April 22 2025

Good information. I appreciate everything you show and tell us. Thank you.

April 22 2025

Hey Matt,

experienced cnc-miller and programmer form south germany here: Your explanation is very good and absolutely right. -there is nothing to add.

Your YouTube channel is among my favourite ones!

Best regards

Rolf

April 22 2025

Do you ever use any of the 75 degree turn tool holders? I believe that’s what they are called. Basically they just use the sides of your cnmg inserts you don’t typically use. Helps save cost and we have used them for heavy roughing. Only downside is side is that it leaves an angle on the back for cleanup.

April 22 2025

Oh be so careful on how I answer back...... see I had my back to the screen, was making a sandwich when I heard those letters at the end of your testimony. I heard C Nth n CT and when read quickly together, well I turned quick and paid attention!!! No you were not spelling a bad word, or at least one a woman would kill you for using around her. I may of should not shared this with you but since your quick to answer this old man in alaska, hopefully see some of why it alarmed me yet made me laugh... because I had a woman nurse in the room who was just leaving, I asked her to listen and then just remembered to turn on close caption. She did laugh because of our specially good humor and relationship as her being my lymphoma nurse. Your son is growing quick and shall be a large young man if he fills your shoes