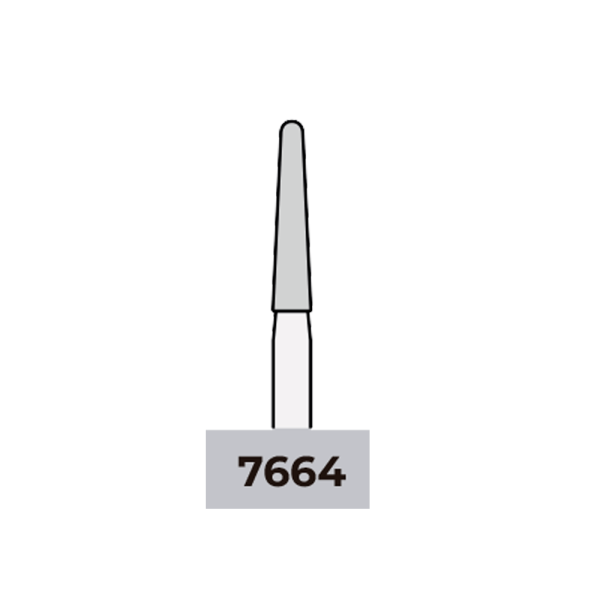

Brocas > Broca Carbide >

Broca Carbide Ca 1/4 - Kavo

Histórico de preços

Ficha Técnica e Modo de uso:

Broca Carbide Ca 1/4 - Kavo

Como quem comprou avalia este produto

April 22 2025

Carbide is king, engineering shops have been using them for 30 years so why not Woodworking

April 22 2025

Best description of use for different tips I have yet seen. Thanks.

April 22 2025

Thanks - looking to buy a set like this as had my regular non carbide set for 7 years and just what I needed to see and hear.

April 22 2025

I am new to turning. Yesterday a friend who has been turning bowls for many years, invited me to learn some basics and get started on a bowl from a 12 inch diameter blank. I guess it was a trial for me to decide if I wanted to get my own equipment. Sharpening is an issue for me, as in the work area I have; I dont want to make sparks that might cause issues with other equipment that have combustible fuel engines, that share my work space. I could include with my turning system, something like a tormek sharpening system, thereby adding more initial cost, or I could start with replaceable carbide tip tools. Thank you for your video!

April 22 2025

I am still researching to determine if I will buy wood turning machinery and tools. It seems that Easy Wood Tools gave me a reason to get started with my own equipment. But now I wonder if EWTools are a starting point for new turners who eventually replace the carbide tipped tools for conventional tools that need shaping and sharpening on a grinding wheel.

April 22 2025

The detailing tip can be used for way more than just to put lines in as shown , I use it to hollow out bowls with ease.

April 22 2025

Where I can sell carbide tool scrab for good price. Please help me. I have 15kg of scrab

April 22 2025

Easy to sharpen these carbide cutters, use a very fine diamond lap, (cheap imports work well) put the cutter face down flat on the diamond lap, use WD40 as a lube to clear the plate clean and place a finger tip flat down on the cutter and just make figure eight strokes until the WD40 solution turns black. No need to press hard, just a few minutes and the cutter is like new. Can be resharpened many times as very little material needs to be removed due to the design of the cutters. The carbide tool shapes have a very wide range of uses-very versatile.

April 22 2025

‘Saves all that time to sharpen’? Takes me about 20s to adjust my pro-edge and sharpen a gouge, while the cutting works twice as fast easily, and leaves a much better finish, so no endless sanding after

April 22 2025

You cant turn the square cutter head to point forwards and make v grooves , it wont seat in the recess

April 22 2025

One should be well above center on outside turning and well below center on inside turning to avoid the dreadful catch!!!!

April 22 2025

"V grooves", sounded a bit like "the grooves", which was confusing for a minute, without a demonstration.

April 22 2025

Wow! I’m sorry but you are not an authority on carbide tools basically on your first attempt. Telling everyone watching that they are only to be used flat on the rest and horizontal to the piece is absolute rubbish! If you round the bottom corners of the tool stock or have the carbide cutters that have a round shaft, you can easily rotate them to approximately 45 degrees and drop the handle of the tool and cut only on the supported side of the cutter, like say a bowl gouge, you can slice the wood cleanly and with very little rotational torque on your hands. Used flat, horizontal they are yes scrapers BUT you can present a bowl or spindle gouge as a scraper also and get crappy tear out as you will with carbide and instantly dull your tool in the process BUT again it’s how you present the cutter to the wood! Scrapers with burrs are an exception and we won’t go there and I use them and traditional tools a lot. I probably average 5 hours a day, 5 days a week on the lathe. I’m a turning instructor in Durango Colorado at the Maker lab. I’m all in and I really don’t like people dismissing carbide tools as crude scrapers. Trust me, I can cut as cleanly as a gouge in many situations and I can and do sometimes not need sandpaper before finishing. I usually do just to be consistent but I seldom have to go coarser than 220 grit, just to remove slight tool marks and slight burnishing occasionally, like a gouge can leave. Touch it up with 320 grit and I’m done. Beautiful finish in 2 minutes often of sanding. You may not believe me but it’s true. Before you blanket statement that carbide cutters are only scrapers you should at least try to apply the rule of 45 degrees for slicing wood, and rotate the tool and drop the handle like a bowl gouge and cut only the supported side of the fulcrum on the corner of your tool steel (rounded and smoothed to avoid digging into your rest) and lead the cutting edge with your handle which accomplishes a near 45 in 3 separate planes on the piece. If you do you will see that carbide cutters are much maligned! I can slice wood like butter and in hard dry, or dirty, or slilica containing wood it cuts (not scrapes) better than traditional and I don’t have to go to the grinder 2 or 3 times on silica/dirty woods. I can cut 10 bowls inside and out before feeling it’s getting dull enough to do something about it. First thing is rotate the cutter on the tool. On round cutters, a 1/3 rotation is perfect. This will give you a perfectly sharp cutting edge for another 10 pieces, and when I have rotated it completely around around three times, you can easily sharpen it. I have multiples of these cutters that are very cheap that I can put a new one on in less than a minute and I’m good to go again for another month or I can take that carbide cutter off and put it on a very fine stone normally starting at 1200 grit and I have a 3000 grit ceramic stone that I can polish the top surface of that carbide in a couple of minutes and it is like brand

April 22 2025

I read the description of your video like this video was done five days ago not five years ago. You may have changed your ways of using carbide cutters if you continued with them, but I don’t know that but my long message on this concept is still true to anyone that is reading it. Anyway, I thought this was new content, not five years old and that’s why I was responding the way I did. Scott.

April 22 2025

I’m confused! Glenn Teagle insists that carbides are CUTTERS. Whereas, you state that carbides are SCRAPERS.