Filtre os resultados

Categorias

Ferramentas > Acessórios para Ferramentas > Soldado > Eletrodos para Solda >

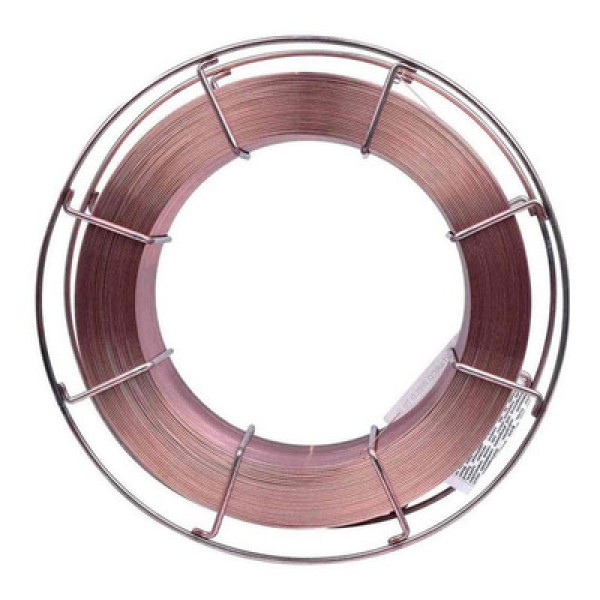

Arame Mig 1,20mm Esab ER70S-6 15Kg

Histórico de preços

🔥NEW VIDEOS EVERY MONDAY AND FRIDAY 🔥n►SUBSCRIBE: https://goo.gl/FRdNssnnToday we got the chance to test out some different ER70S-6 Wires (all with different coatings). The goal was to see if there was any discernible difference in operator appeal as well as arc characteristics. We tested three different wires:nnER70S-6 with Copper Coating (Industry Standard)nER70S-6 with Non-Copper CoatingnER70S-6 with Bronze CoatingnnEQUIPMENT WE USE:n▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬n► Airgas Gas Products: www.airgas.comn► Tab and Slot Welding Tables: www.tabandslot.comn► ESAB Power Sources: www.ESAB.comn► Everlast Power Sources - www.everlastgenerators.comn► AHP Power Sources - www.ahp.comn► Plymovent Fume Extraction - www.plymovent.comn▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬nJOIN US ON:n▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬nn► FACEBOOK : https://www.facebook.com/welddotcomnn► INSTAGRAM : https://www.instagram.com/welddotcom/ #welddotcomnDisclaimer: Weld.com is compensated for providing links in our descriptions. However, we only work with companies that we use ourselves and can honestly and ethically recommend to our audience.

Ficha Técnica e Modo de uso:

Unidades por embalagem: 1 | Peso: 15 kg | Diâmetro: 1.

2 mm | Fabricado em aço.

| Material de revestimento do eletrodo: arame solido cobreado.

| Com corrente CA.Características principais

Esab 000000000000740534 1,2 mm 15 kg Outras características

Aço ARAME SOLIDO COBREADO CA

O Arame Mig 1,20mm Esab ER70S-6 15Kg inclui o residual existente no aço mais o revestimento.

O arame para solda para o processo MIG/MAG tem as características físicas e químicas rigorosamente dentro das especificações da norma AWS ER 70S-6 e DIN 8559.

Por suas excelentes propriedades mecânicas, permite um ótimo funcionamento na alimentação automática no processo de soldagem.

A qualidade e alta produtividade deste tipo de solda a tornam indicada para rígidos processos de fabricação em solda em aço de baixo carbono.

Ideal para processo de solda Mig.

Dados Técnicos:

- Código do fornecedor: 740534

- Modelo: ER70S6

- Diâmetro: 1,20mm

- Processo de soldagem: MIG/MAG

*Imagens meramente ilustrativas.

Como quem comprou avalia este produto

April 24 2025

Good job i like how your welding looks good even if you have at least 60 years :)

Im aiming to the same goal maybie to becoma a welding instructor just like you!

April 24 2025

Nice stuff I like them all. Except in Michigan the cu free wire might just rust with the quickness...idk though.

April 24 2025

i heard another gas when you first started welding what gas is that

April 24 2025

Can u do a video on how safe it is to weld with open air 7018, and how that would vary from a dry 7018. Or would that be like a 7014 since its no longer a low hydrogen rod

April 24 2025

So the noise in the beginning of you welding......is that a primary or secondary gas??

April 24 2025

Would be neat to see new wire vs old corroded/dirty wire side by side test.

April 24 2025

Right on another weld.com video! I wasnt aware ER70S-6 had different coatings I just thought it was copper.

Very cool. Thank you for this video!

comment no20

thumbs up no141

April 24 2025

Hi Mr. Moffat,

You have such a well polished delivery and comfortable presence in front of the camera it is a pleasure to watch every video. I am teaching myself to weld and this is the next best thing to experience.

April 24 2025

My company uses 0.035 ER120-1 wire on spray transfer with 92/8 gas. They use the MidAlloy brand and let me tell ya what, its some of the crappiest wire Ive ever ran. Luckily I weld some 2519 Aluminum so I dont have to use it.

April 24 2025

I have never figured out how to run a mud gun,but your videos show you sure can.

April 24 2025

Hey Bob, love your work. been in the welding trade most of my life. love learning. You might like a young guy from Alberta Canada. travis field . He is a well rounded young man, pipeline , Tig ,stick. seems to do it all. lots of talent.he has a bunch of video’s on you tube, Feildres i believe is his you tube handle.

April 24 2025

Would be interesting to compare how the wire (on the spool) holds up overtime. I weld some but not daily. My garage is not air conditioned and I wonder if the copper free would corrode more over time in my scenario. Nice video. Thanks

April 24 2025

I think it would be interesting to do a comparison in the flat position of the same 3 wires in "Spay" mode. You mentioned being able to significantly increase the wire speed with the uncoated wire. I bet it would really shine in spray transfer

April 24 2025

the copper free sounds beautiful and looks great. would be nice to compare penetration on all of those

April 24 2025

And another great video in the books! Thanks for the very interesting info. Makes me curious what the designers had in mind as an application for the different wire coatings. If the wire type is the same are there different applications for the different coatings and what reasons would they have for using the different coatings. Different coatings for different materials or whatever. Curious. Great video! Thanks Bob.

April 24 2025

Good info bob. I believe im gona try the bare wire next. Looked like something i would like for clean automotive welding.

April 24 2025

im wanting to get started on a project. i will be welding stainless steel and copper. i was going to buy a mig/stick welder cheap one. ive never welded before so i know ill need some practice first ive been watching your videos and lots of others. will a mig/stick welder get the job done or do i absolutely have to buy a tig machine?

April 24 2025

i use non coated. less fumes, less spatters.

the price is quite similar, i pay 1.66 € /kg for the coated and 1.77 for non coated.

April 24 2025

I weld with copper free wire, but already tired to pay 40 e for 15kg spool and will start using coppered wire for 20e the same weight spool.

April 24 2025

Old vid but i whas wondering where al the used wires the same brand? I wanted to try the Esab Aristorod 12.50 non coper coated wire

April 24 2025

The big differance is that the coating breakes after a while and the chips remains in the liner and drag with the moving wire to the weld pool and contaminating it. non coated is better.